LCM4487 Diving Bell Lifting System

For this project, we were contacted by a manufacturer of diving equipment, who were interested in having custom design load pins manufactured that were suitable for use in a marine/offshore environment. Because they would be used in a lifting application that involved personnel, the traceability requirements were high, with 3.1 material certificates and charpy testing required. These load pins were required to measure the loads applied to the handling systems of the diving bells.

The diving bells are lifted ready for deployment through a dedicated opening in the centre of the vessel called a moon pool, and are also recovered using the same lifting system. Next to the moon pool there are a series of vertical sheaves, which connect to the diving bell. The plan was to have load pins installed in these sheaves to determine the weight of the diving bell. This would ensure that there were no overload situations, which could potentially endanger the personnel inside.

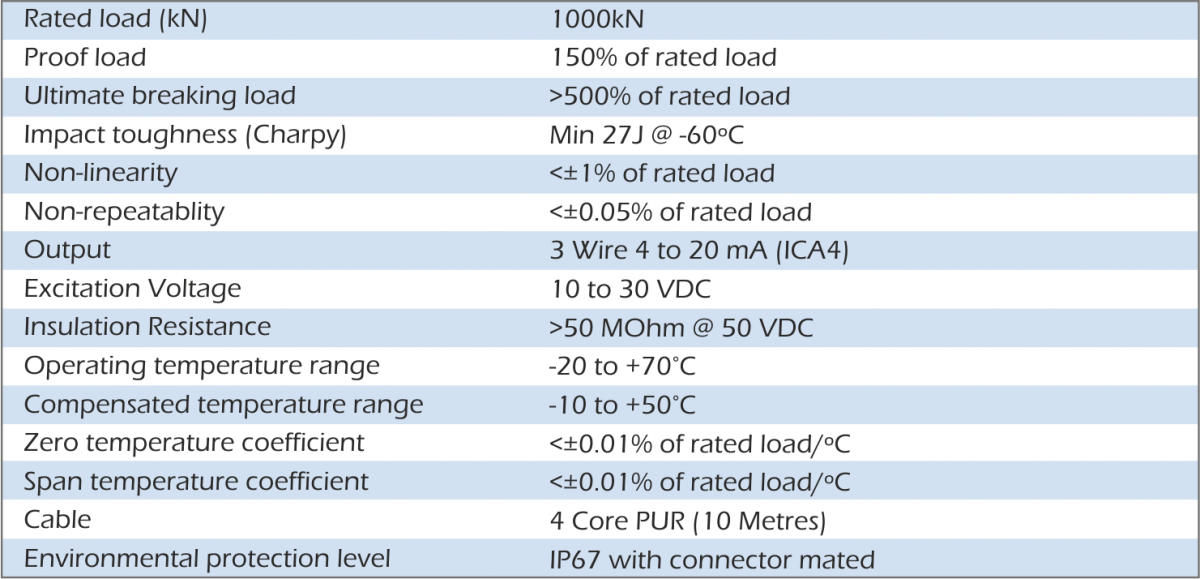

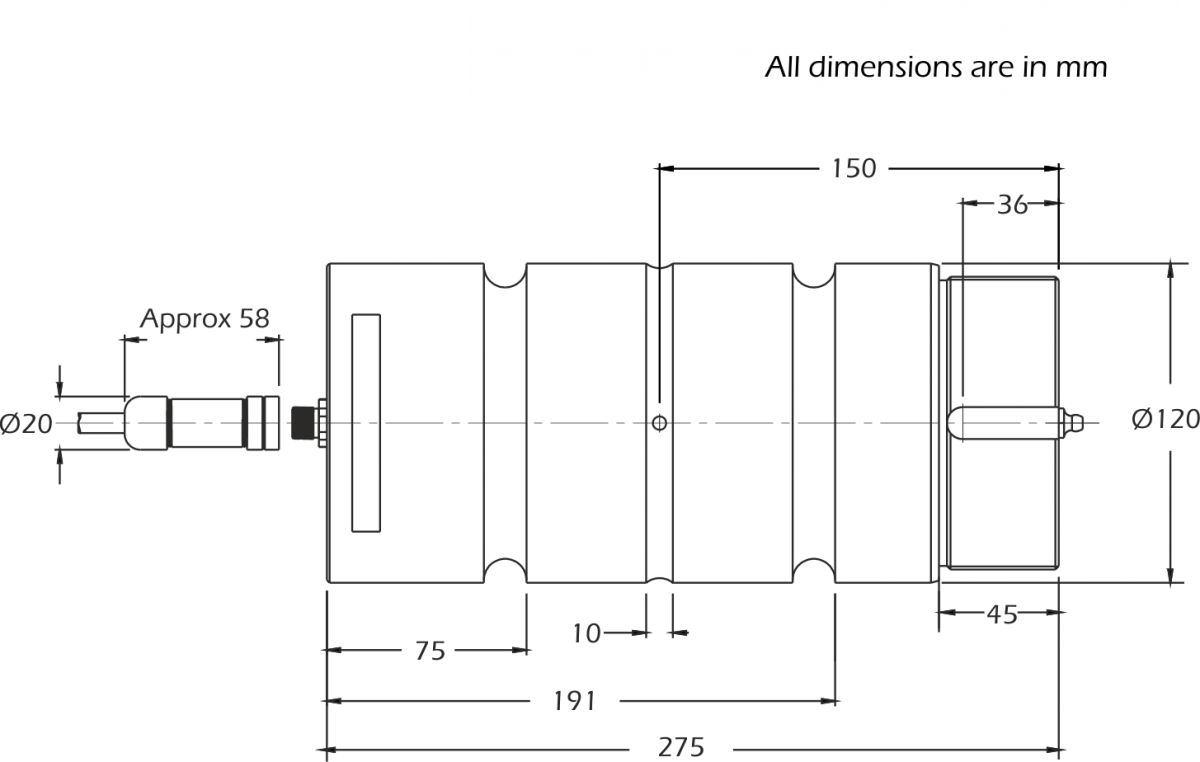

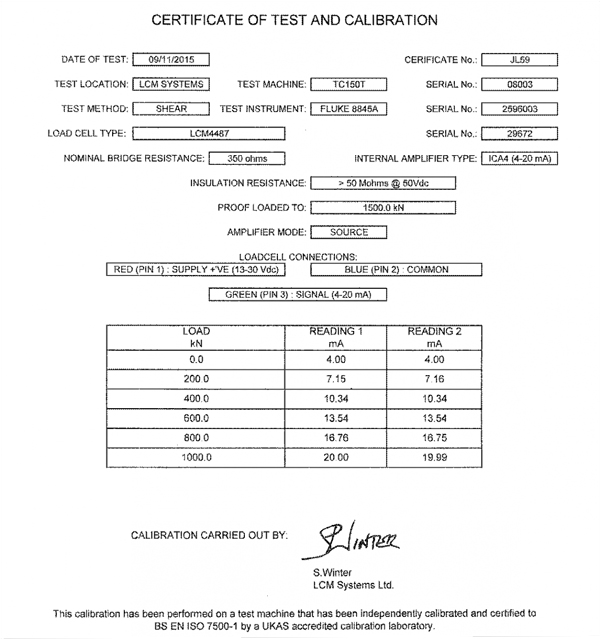

Four load pins are installed per moon pool lifting system, each rated to 1000kN. Manufactured from stainless steel and with environmental sealing to IP67 for suitability in a marine environment, the load pins feature an internal amplifier to provide 4-20mA output. This allows the load measurement data to be exported direct to the vessels PLC system, where the results can be displayed and monitored for safety purposes.

The load pins were designed, manufactured and delivered within the required time frame, and the customer was very happy with their performance. They have since gone on to place orders for several more systems.

The main criteria for the project were as follows:

- Load pins must be suitable for use in a marine/offshore environment

- Load pins must have a greasing hole with M10 x1 connection and M110 x 2 external thread

- Charpy testing required

- Certificate of conformity required

- 4-20mA output required for direct import to PC/PLC

- Full material traceability required

- Calibration certificate required