LCM4520 150mm Displacement Transducer

We received an email enquiry from a customer looking to replace some displacement transducers they had purchased some years ago. These displacement transducers were being used to detect any linear movement in accelerators installed in the accelerator complex at CERNs underground laboratory on the French/Swiss border near Geneva (ariel view of complex shown below). These accelerators include the renowned Hadron Collider, which all work together to push particles to nearly the speed of light for scientific research. The displacement transducers are fixed into position over a weld or joint in various strategic points along the pipework, and if the joint/weld starts to pull apart, the extension rod moves in proportion to the level of displacement. Fractions of a mm can be detected, giving warning of any movement well in advance of any failure. In a laboratory the scale of the accelerator complex, any equipment breakdown could be catastrophic, so monitoring of structural integrity vital to the continued success of the project.

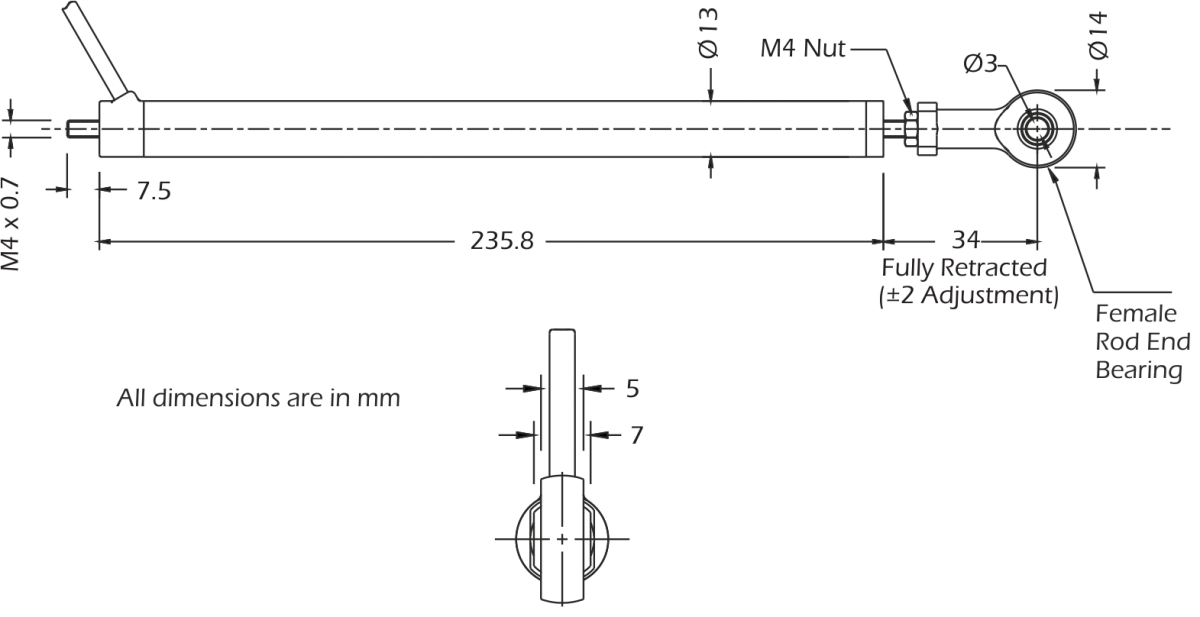

As the displacement transducers they had previously used were no longer manufactured and had been replaced by a newer model, the customer asked if they could have some modifications to better suit their application. Instead of having female rode end bearings at both ends they wanted the cable exit end modified to have a male rod end fitted to the actuator instead, with a 3mm rod end bore. This was because they didn’t use the bearing fixing system at this position, as the displacement transducer is clamped into place by the transducer body. Additionally the slight reduction in length would be beneficial in facilitating installation. LCM Systems made the required design amendments to the product, and ten were ordered for trial purposes.

The displacement transducer performed as expected and the custom design changes much better suited their requirements. As a result a further one hundred were ordered; enough to meet their requirements for the next 4 to 5 years.

The main criteria for the project were:

- Must have 150mm electrical stroke

- Required a female rod end bearing one end, and a 3mm rod end bore at the other

- A reduced length to aid installation

- A 13mm diameter body (same as the previously used product)

- 4 week delivery schedule

- 150mm electrical stroke

- Body diameter of 13mm

- Detects linear movement

- Displacement Transducer

- Life at 250mm per second greater than 100 million operations

- Low noise

- Sealing to IP55

- Very high resolution (virtually infinite)