LCM4823 Tension Monitoring of Telescope Vanes

An international astronomical observatory is manufacturing a new instrument called WEAVE for the William Herschel Telescope (WHT) that incorporates wireless load pins developed by LCM Systems. The WHT is operated on behalf of the UK Science and Technology Facilities Council (STFC), the Dutch Nederlanse Organisatie voor Wetenschappelijk Onderzoek (NWO), and the Spanish Instituto de Astrofísica de Canarias (IAC). There is a requirement for remote monitoring of the tensile forces in the telescope vanes. The wireless load pins are part of the assembly that determines preload force to ensure the positional alignment and accuracy of the approximately 4 tonne WEAVE optical corrector. This new multi-object survey spectrograph will allow astronomers to take optical spectra of up to 1000 stars and galaxies in a single exposure (currently only 150 objects can be observed simultaneously).

The telescope vanes are subject to a tensile force by tightening turnbuckles and operators need to know that force. Force measuring load pins provide invaluable information on the amount of preload the vanes are subject to and load monitoring ensures that the preload is applied equally to each of the eight vanes, as well as providing the combined force applied.

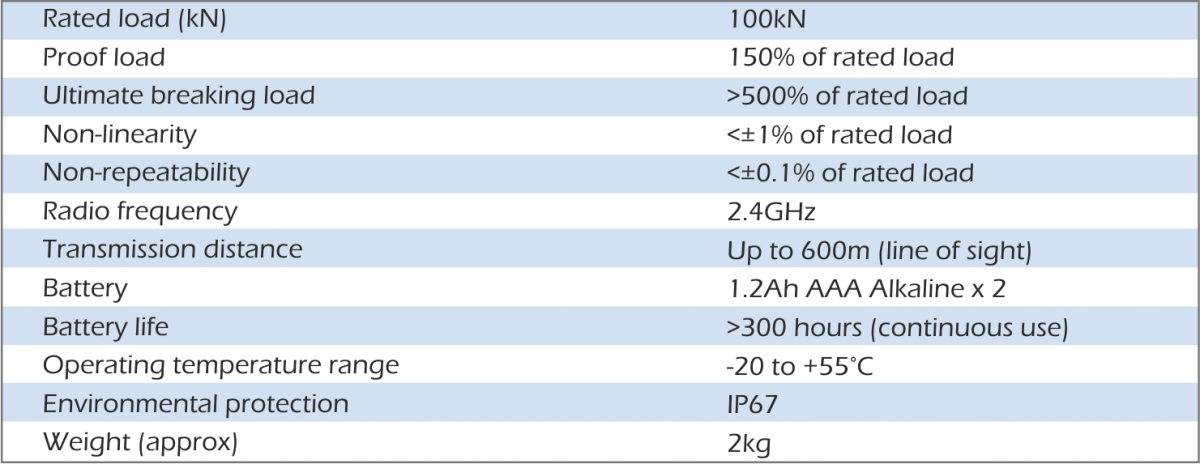

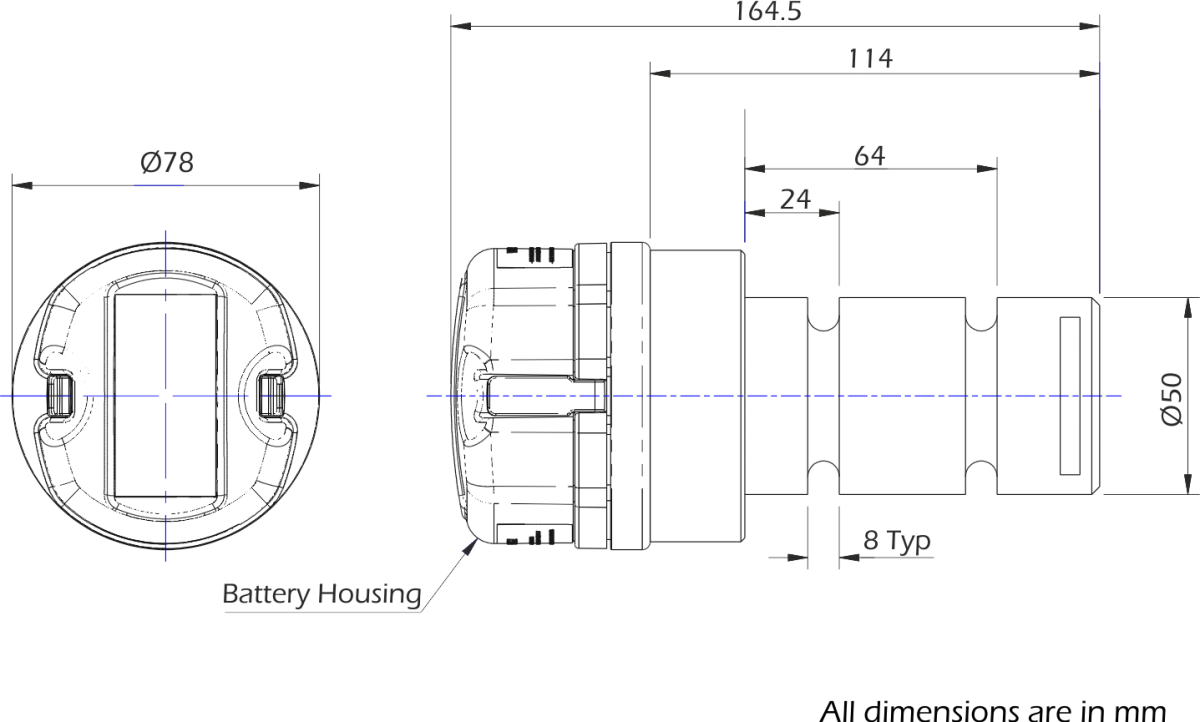

Because of the multi-positional handling frame a cabled measurement solution was not practical, so the customer required a wireless system. LCM Systems designed and manufactured 8 x 100kN wireless load pins to fit in the vanes. The pins utilise our unique telemetry housing, which is manufactured from tough high performance polyamide resin, making it strong yet light and resulting in a better balanced load pin. The built in radio telemetry electronics provide a 600m transmission distance and over 300 hours' continuous use battery life.

In addition to the 8 wireless load pins, a T24-HA handheld display was supplied to show the individual loads on each vane, as well as the total load.

The main criteria for the project were as follows:

- 8 x 100kN rated wireless load pins required

- Must have a diameter of 50mm to fit pre-drilled vane turnbuckle

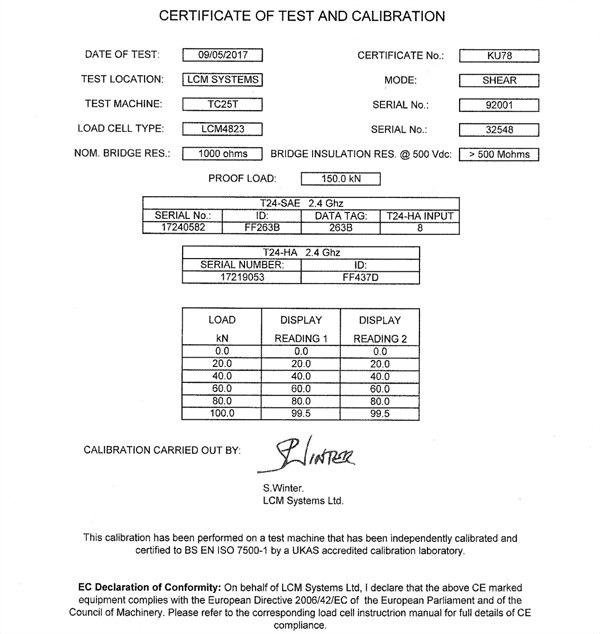

- Must be Machinery Directive compliant and CE marked

- Display needed to show tension readings for each vane, as well as total load

- Certificate of conformity required

- Calibration certificate required